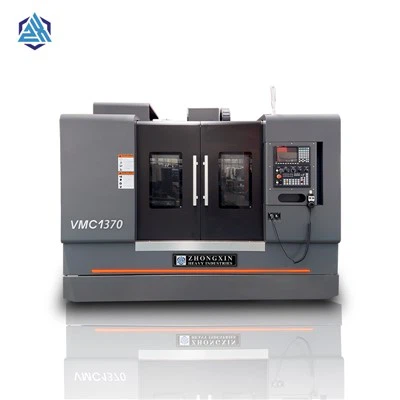

Vertical Machining Center Vmc 1160

USE

The VMC 1160 vertical machining center is a top - tier manufacturing solution, engineered to bring unrivaled precision and efficiency to your production lines. This advanced machine is a game - changer for industries that demand high - quality machining results.

Features

Robust Structure for Ultimate Stability

Constructed with heavy - duty, high - grade cast iron, the VMC 1160's machine body offers outstanding stability and vibration dampening. The optimized design, based on in - depth finite - element analysis, ensures maximum structural integrity. This allows the machine to maintain consistent accuracy even during the most demanding machining operations. The solid foundation minimizes the impact of external forces, resulting in smooth and reliable performance over the long term.

Precision - Driven Motion System

Equipped with high - precision linear guideways and precision - ground ball screws, the VMC 1160 delivers exceptional motion control. The X, Y, and Z axes feature a travel range of 1100mm×600mm×600mm, providing ample space for large - scale workpiece processing. The positioning accuracy of up to ±0.005mm and repeat positioning accuracy of ±0.005mm guarantee that every cut and contour is executed with utmost precision. Whether it's intricate mold making or complex part manufacturing, the VMC 1160 meets the strictest tolerances.

High - Performance Spindle Unit

The heart of the VMC 1160 is its powerful spindle system. It can achieve a maximum spindle speed of 8000rpm as standard, with an optional upgrade to 12000rpm for applications that require even higher speeds. Driven by a high - torque servo motor, the spindle can generate substantial cutting force, making it suitable for a wide range of materials, from soft aluminum alloys to tough steels. A built - in spindle cooling system ensures stable operation during continuous high - speed rotation, effectively reducing thermal deformation and maintaining machining accuracy.

Efficient Automatic Tool Changer

The VMC 1160 comes with an automatic tool changer (ATC) that significantly enhances productivity. With a standard tool capacity of 24 tools (expandable to 32 tools upon request), the ATC enables quick and seamless tool changes. The tool - to - tool change time is a mere 1.8 seconds, minimizing non - cutting time and keeping your production process running smoothly. This feature is especially beneficial for multi - process machining operations, allowing for rapid transitions between different cutting tasks.

Friendly Control System

Operating the VMC 1160 is a breeze, thanks to its intuitive and user - friendly control system. The advanced CNC controller offers a wide range of functions, including easy - to - program machining cycles, real - time monitoring of machining parameters, and diagnostic capabilities. This not only simplifies the operation process but also improves overall production efficiency. Whether you're a seasoned operator or a new user, the control system of the VMC 1160 ensures a seamless and productive machining experience.

Versatile Application Scenarios

The VMC 1160's capabilities make it suitable for a diverse range of industries. In the automotive industry, it can be used for manufacturing engine components, transmission parts, and chassis components. In the aerospace sector, it is ideal for machining complex aircraft parts made from high - strength alloys. The mold - making industry also benefits from the VMC 1160's precision and versatility, enabling the production of high - quality molds for plastic injection, die - casting, and forging processes.

The Vertical Machining Center VMC 1160 is a comprehensive machining solution that combines advanced technology, high - end components, and user - friendly design. It is the perfect choice for manufacturers looking to enhance their production capabilities, improve product quality, and stay competitive in the global market.

Specifications

|

SPECIFICATIONS FOR VMC1160 VERTICAL MACHINING CENTER |

||

|

Table size Table Max. load |

mm kg |

1200x600 1000 |

|

X/Y/Z axis travel Dist. between spindle and column guide surface |

mm mm |

1100x600x600 650 |

|

Dist. between spindle end face and worktable surface X/Y/Z Max. feed speed |

mm mm/min |

120-720 10000 |

|

X/Y/Z Max. rapid traverse Spindle Max. speed |

m/min r/min |

32/32/30 8000 |

|

Spindle taper hole Spindle motor |

type kw |

BT40 11/15 |

|

X/Y/Z axis servo motor X/Y/Z guide rail form |

kw

|

4/4/5 Direct connection Hard guide way |

|

The workbench T slot Repeat positioning accuracy Tool magazine |

mm mm

|

5-18x100 +/-0.005 Disk |

|

Tool capacity Maximum tool weight Max. tool length |

kg mm |

24 Disk 8 300 |

|

Electric capacity Machine size(LxWxH) Net. weight(about) |

kVA mm kg |

18 3100x2490x2380 7000 |

Hot Tags: vertical machining center vmc 1160, China vertical machining center vmc 1160 manufacturers, suppliers, factory, Manual Turret Lathe, , Ck6130 CNC Lathe, , Lathe Milling Machine Combo 3 in 1

You Might Also Like

Send Inquiry